CSF Cooling

CSF PORSCHE 991 TURBO - TURBO S INTERCOOLERS

Regular price

$2,995.00

Shipping calculated at checkout.

CSF Cooling is proud to announce the official public release of its Porsche 991 Turbo & Turbo S high performance intercoolers for both 991.1 & 991.2 models. Since the intercoolers made their official world debut at the 2017 SEMA show, a unique sales decision was made to only release these intercoolers (for a period of 1 year) to a select group of the world’s most highly regarded Porsche motorsport ECU tuners and vehicle builders. Over the past year, CSF’s Porsche 991 Turbo intercoolers have been race-tested, logged, and fully validated by some of the world’s best Porsche tuners. These intercoolers have been regarded as the “Go-To” option for the best performance and value available in the performance aftermarket.

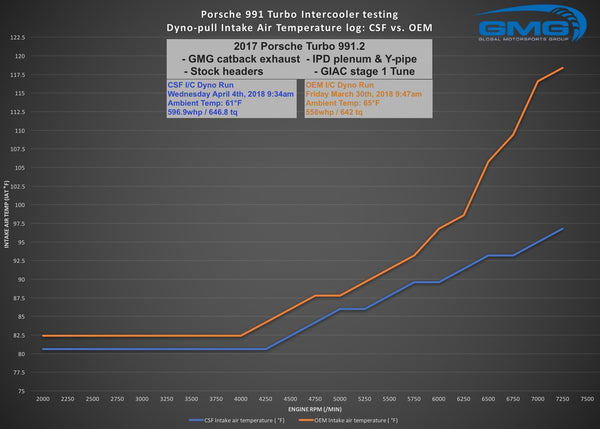

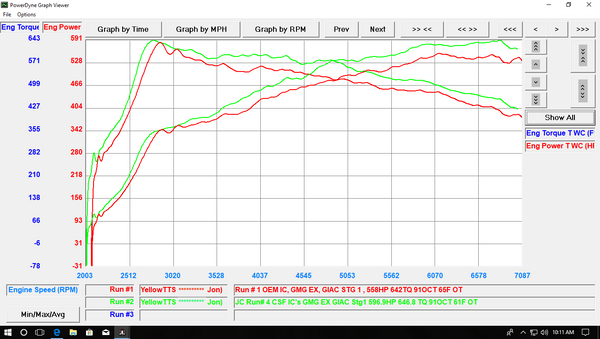

Validation of CSF’s Porsche 991 Turbo Intercoolers started with a GMG Racing modified vehicle with typical bolt-on modifications and a stage-1 tune from GIAC. Extensive dyno testing was completed over a 4-day period with similar ambient air temperatures in a controlled dyno cell and were conducted at similar times in the day (Early morning and afternoon to control air density variability). These tests consisted of several real-world test simulations with data proving a massive increase in performance and heat rejection of the CSF Porsche 991 Turbo Intercoolers.

4th gear dyno pull at wide open throttle (WOT) resulted in:

-Intake air temperatures (IAT’s) delta of the CSF intercoolers were ~20°F lower than the -IAT of the OEM Porsche intercoolers

-CSF IAT’s at end of 4th gear pull ~97°F (~36°C)

-OEM IAT’s at end of 4th gear pull ~118°F (~48°C)

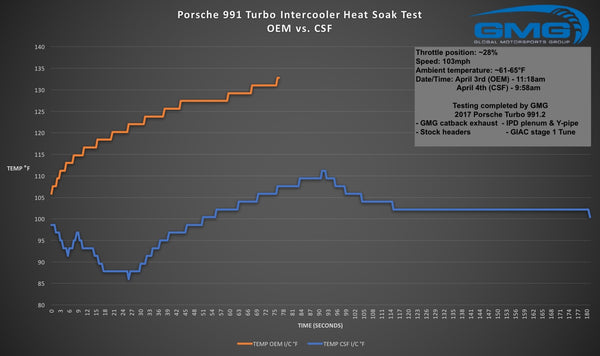

3-minute heat-soak test resulted in:

-Data logs proving that the CSF Porsche 991 Turbo intercoolers keep IAT’s consistently 25 – 40°F degrees less than the OEM Porsche intercoolers.

-IAT’s of the CSF Porsche 991 Turbo intercoolers start at ~98°F (~37°C). For the first ~30 seconds, IAT’s are actually reduced by ~10°F before increasing to no more than ~15°F before again reducing to a steady and consistent ~103°F (~39°C)for the remainder of the test (only 5°F delta from start).

-IAT’s of the OEM Porsche intercooler start at ~105°F (~40.5°C). Immediately IAT’s start to increase, and after only ~30 seconds, IAT’s have already increased by 20°F. IAT’s increase towards a 30°F delta when the technician decides to abort the OEM testing at only ~75 seconds into the test due to high IAT’s reaching levels of decreased vehicle performance.

-*CSF is the only manufacturer in the 991 Porsche Turbo intercooler aftermarket to undergo and publish this type of data and testing results*

Dyno Testing analysis:

-CSF’s wind-tunnel optimized 4.5 inch (115mm) width bar/plate core, is a significant improvement over the OEM designed 3.14 inch (80mm) tube/fin core. Furthermore, CSF’s exclusive thermal dispersion heat transfer coating is able to reject heat ~35% more efficiently than the raw/uncoated aluminum core of the OEM intercooler. The coating is applied in California, USA by an aerospace coating company who also supplies coatings for Boeing. This unique coating is a key feature to achieving world-record performance, exclusively available from CSF.

SPECIFICATIONS

F-its both 991.1 & 991.2 Turbo/Turbos S vehicles. (2013-2019)

-3D Scanned, CAD Designed and 3D-printed prototype; Tested in collaboration with automotive engineering firm RK Autowerks. Providing the absolute best fitting Porsche 991 Turbo intercoolers available in the aftermarket.

-CFD tested (Computational Fluid Dynamics) cast end tanks with several post machining processes for the absolute best tolerance specifications and maximum airflow distribution throughout the core.

-All OEM mounting points are retained with the OEM clip-in hardware design. Utilizing factory hardware, for an OEM-level installation. (CSF Exclusive)

-OEM style “Quick-Connect” machined fittings for precise fitment, lock and seal.

-Finished with an aerospace grade, nano-particle, heat dispersion coating that dissipates heat ~35% better than uncoated raw aluminum. (~ $500.00 value)

-“Drop-in fitment”, no modifications or grinding to metal brackets, etc.

(Requires slight trimming to the plastic intercooler shrouds – instructions included and available for download at www.CSFrace.com)

-Individually leak / pressure tested to 120 PSI

-Individually inspected for quality control

-Instruction manual included CLICK HERE TO DOWNLOAD

-Specifically cut foam protective packaging to ensure damage free shipment

-Manufactured completely in house by CSF; a tier 1 OEM manufacturer with over 50 years of cooling system manufacturing experience. Over 500,000 units sold every year and over 40 million units sold globally.

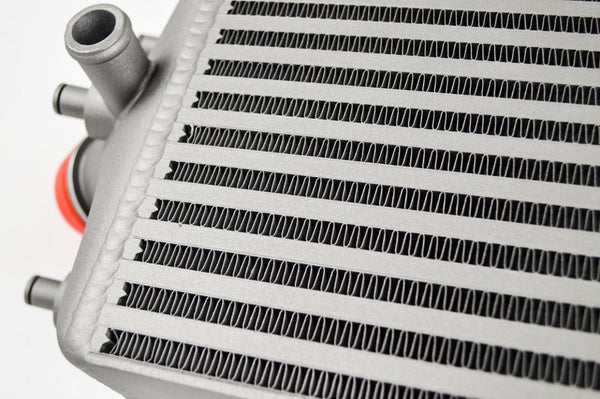

CORE DESIGN

-8mm fin height louvered external fin with 6.5mm fin height staggered internal fin. -Designed to maximize surface area contact and heat dissipation.

-Wind tunnel optimized and dyno tested for low pressure drop with best performance

-CSF’s “Ultimate-Boost” High-performance bar / plate core. Built in house and pressure tested to 120 PSI

-4.53-inch thick core compared to OEM’s 3.15-inch core (115mm vs 80mm)

-Increased flow area by 43.75%

-Increased surface area by 70% (8.5m^2 vs. 5.0m^2)

-Built in-house by CSF (Only high-performance company to manufacture their own intercooler cores)

-From first glance the increase in width from the OEM’s 80mm core to the CSF’s 115mm width is very apparent. Critical for vehicles running performance tunes with bolt-on modifications. Considered a mandatory upgrade for vehicles running upgraded turbo systems. The larger capacity CSF bar/plate core design can handle significantly more airflow + increased boost pressures compared to the OEM intercooler system.

-CSF’s 100% TIG welded cast end tanks, paired with its high-efficiency bar/plate intercooler core. Compared to the OEM style tub/fin core, which is crimped on to the plastic end tanks. The weaker OEM design can crack under high boost or vibrations typical to race conditions.

-The design of CSF’s end tanks allows for airflow to be distributed evenly throughout the entire intercooler compared to the OEM intercooler design which is much shallower. The OEM design makes it more difficult for airflow to reach the top/bottom tube sections at the ends of the intercooler.

-CSF’s Porsche 991 Turbo intercoolers are finished with an aero-space grade, Nano-particle, heat dispersion coating that dissipates heat ~35% better than uncoated raw aluminum. The OEM intercooler system has a raw finished core.

CSF takes pride in the R&D behind each new product that it releases. Striving to continuously develop industry leading performance cooling systems, CSF not only analyzes OEM samples, but often leading competitor’s products to see where performance gains can be achieved. In comparison to the By Design intercoolers shown in the pictures above. CSF’s proven design has the following advantages:

-Larger volume end tanks. Allowing for airflow to be distributed evenly throughout the entire intercooler where as the competitor’s end tank design is shallower, similar to OEM.

-CSF chose to invest in high-cost tooling for precision cast end tanks after undergoing -CFD analysis to achieve more difficult shapes. This results in better airflow and fitment versus more expensive to produce CNC machined end tanks (often having limitations in both design and manufacturing phases)

-CSF utilizes ALL factory mounting points to ensure the unit is properly secured. CSF’s engineers made sure OEM mounting pin connections were utilized and proper clearances were made. No grinding to the metal intercooler cage is necessary to install. (By Design and some other competitors require metal grinding for their intercoolers to be installed).

-CSF is the only company to include a heat dispersion coating with its Porsche 991 Turbo intercoolers. (~$500 value)

The best value in terms of performance, fitment, and weight available on the aftermarket. Competing intercooler systems range from $1,000-$3,000 USD more than -CSF’s Porsche 991 Turbo intercoolers with less published data and verified results. Why pay more for less?

Validation of CSF’s Porsche 991 Turbo Intercoolers started with a GMG Racing modified vehicle with typical bolt-on modifications and a stage-1 tune from GIAC. Extensive dyno testing was completed over a 4-day period with similar ambient air temperatures in a controlled dyno cell and were conducted at similar times in the day (Early morning and afternoon to control air density variability). These tests consisted of several real-world test simulations with data proving a massive increase in performance and heat rejection of the CSF Porsche 991 Turbo Intercoolers.

4th gear dyno pull at wide open throttle (WOT) resulted in:

-Intake air temperatures (IAT’s) delta of the CSF intercoolers were ~20°F lower than the -IAT of the OEM Porsche intercoolers

-CSF IAT’s at end of 4th gear pull ~97°F (~36°C)

-OEM IAT’s at end of 4th gear pull ~118°F (~48°C)

3-minute heat-soak test resulted in:

-Data logs proving that the CSF Porsche 991 Turbo intercoolers keep IAT’s consistently 25 – 40°F degrees less than the OEM Porsche intercoolers.

-IAT’s of the CSF Porsche 991 Turbo intercoolers start at ~98°F (~37°C). For the first ~30 seconds, IAT’s are actually reduced by ~10°F before increasing to no more than ~15°F before again reducing to a steady and consistent ~103°F (~39°C)for the remainder of the test (only 5°F delta from start).

-IAT’s of the OEM Porsche intercooler start at ~105°F (~40.5°C). Immediately IAT’s start to increase, and after only ~30 seconds, IAT’s have already increased by 20°F. IAT’s increase towards a 30°F delta when the technician decides to abort the OEM testing at only ~75 seconds into the test due to high IAT’s reaching levels of decreased vehicle performance.

-*CSF is the only manufacturer in the 991 Porsche Turbo intercooler aftermarket to undergo and publish this type of data and testing results*

Dyno Testing analysis:

-CSF’s wind-tunnel optimized 4.5 inch (115mm) width bar/plate core, is a significant improvement over the OEM designed 3.14 inch (80mm) tube/fin core. Furthermore, CSF’s exclusive thermal dispersion heat transfer coating is able to reject heat ~35% more efficiently than the raw/uncoated aluminum core of the OEM intercooler. The coating is applied in California, USA by an aerospace coating company who also supplies coatings for Boeing. This unique coating is a key feature to achieving world-record performance, exclusively available from CSF.

SPECIFICATIONS

F-its both 991.1 & 991.2 Turbo/Turbos S vehicles. (2013-2019)

-3D Scanned, CAD Designed and 3D-printed prototype; Tested in collaboration with automotive engineering firm RK Autowerks. Providing the absolute best fitting Porsche 991 Turbo intercoolers available in the aftermarket.

-CFD tested (Computational Fluid Dynamics) cast end tanks with several post machining processes for the absolute best tolerance specifications and maximum airflow distribution throughout the core.

-All OEM mounting points are retained with the OEM clip-in hardware design. Utilizing factory hardware, for an OEM-level installation. (CSF Exclusive)

-OEM style “Quick-Connect” machined fittings for precise fitment, lock and seal.

-Finished with an aerospace grade, nano-particle, heat dispersion coating that dissipates heat ~35% better than uncoated raw aluminum. (~ $500.00 value)

-“Drop-in fitment”, no modifications or grinding to metal brackets, etc.

(Requires slight trimming to the plastic intercooler shrouds – instructions included and available for download at www.CSFrace.com)

-Individually leak / pressure tested to 120 PSI

-Individually inspected for quality control

-Instruction manual included CLICK HERE TO DOWNLOAD

-Specifically cut foam protective packaging to ensure damage free shipment

-Manufactured completely in house by CSF; a tier 1 OEM manufacturer with over 50 years of cooling system manufacturing experience. Over 500,000 units sold every year and over 40 million units sold globally.

CORE DESIGN

-8mm fin height louvered external fin with 6.5mm fin height staggered internal fin. -Designed to maximize surface area contact and heat dissipation.

-Wind tunnel optimized and dyno tested for low pressure drop with best performance

-CSF’s “Ultimate-Boost” High-performance bar / plate core. Built in house and pressure tested to 120 PSI

-4.53-inch thick core compared to OEM’s 3.15-inch core (115mm vs 80mm)

-Increased flow area by 43.75%

-Increased surface area by 70% (8.5m^2 vs. 5.0m^2)

-Built in-house by CSF (Only high-performance company to manufacture their own intercooler cores)

-From first glance the increase in width from the OEM’s 80mm core to the CSF’s 115mm width is very apparent. Critical for vehicles running performance tunes with bolt-on modifications. Considered a mandatory upgrade for vehicles running upgraded turbo systems. The larger capacity CSF bar/plate core design can handle significantly more airflow + increased boost pressures compared to the OEM intercooler system.

-CSF’s 100% TIG welded cast end tanks, paired with its high-efficiency bar/plate intercooler core. Compared to the OEM style tub/fin core, which is crimped on to the plastic end tanks. The weaker OEM design can crack under high boost or vibrations typical to race conditions.

-The design of CSF’s end tanks allows for airflow to be distributed evenly throughout the entire intercooler compared to the OEM intercooler design which is much shallower. The OEM design makes it more difficult for airflow to reach the top/bottom tube sections at the ends of the intercooler.

-CSF’s Porsche 991 Turbo intercoolers are finished with an aero-space grade, Nano-particle, heat dispersion coating that dissipates heat ~35% better than uncoated raw aluminum. The OEM intercooler system has a raw finished core.

CSF takes pride in the R&D behind each new product that it releases. Striving to continuously develop industry leading performance cooling systems, CSF not only analyzes OEM samples, but often leading competitor’s products to see where performance gains can be achieved. In comparison to the By Design intercoolers shown in the pictures above. CSF’s proven design has the following advantages:

-Larger volume end tanks. Allowing for airflow to be distributed evenly throughout the entire intercooler where as the competitor’s end tank design is shallower, similar to OEM.

-CSF chose to invest in high-cost tooling for precision cast end tanks after undergoing -CFD analysis to achieve more difficult shapes. This results in better airflow and fitment versus more expensive to produce CNC machined end tanks (often having limitations in both design and manufacturing phases)

-CSF utilizes ALL factory mounting points to ensure the unit is properly secured. CSF’s engineers made sure OEM mounting pin connections were utilized and proper clearances were made. No grinding to the metal intercooler cage is necessary to install. (By Design and some other competitors require metal grinding for their intercoolers to be installed).

-CSF is the only company to include a heat dispersion coating with its Porsche 991 Turbo intercoolers. (~$500 value)

The best value in terms of performance, fitment, and weight available on the aftermarket. Competing intercooler systems range from $1,000-$3,000 USD more than -CSF’s Porsche 991 Turbo intercoolers with less published data and verified results. Why pay more for less?