The release of these three new turbos, the GTX3071R, the GTX3076R and the GTX3582R raises the bar for mid-frame turbo performance. More BOOST and additional FLOW without losing BOOST RESPONSE is result of extensive research and development of a new and more aerodynamic profile of compressor wheels. The GTX3076R can now flow nearly 65 lb/min and the GTX3582R has the potential to do over 750HP in the compact familiar external package of the standard GT turbos we've grown to appreciate. You do not have to change your turbo kit arrangement!

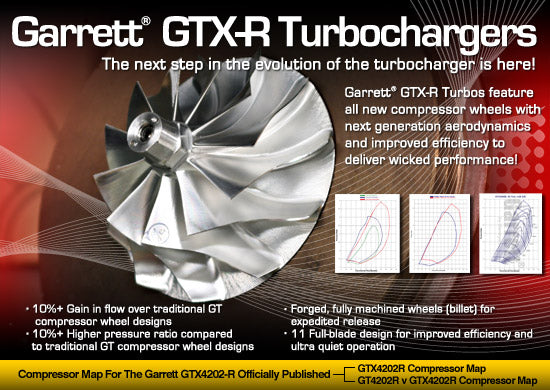

While Garrett by Honeywell is currently the industry leader and the standard in providing ultra-reliable, ultra-high-performance turbos, the Garrett Engineering Team has done it again. Always leading the pack in setting new standards, this latest iteration of turbo innovation comes from applying decades of turbocharger experience and utilizing some of the most technologically advanced tools to model, develop, and test new combinations. With the abundance of CNC machining equipment availability coupled with the wave of idling machine shops and people wanting to work, it's easy to "carve" out a compressor wheel from aluminum blanks and introduce a "billet wheel" to the turbo marketplace. Garrett's GTX wheel is not just another "billet wheel." Garrett's forged, fully machined wheels allow quicker deployment of their aerodynamics to the marketplace.

While more expensive to make PER UNIT, this PROCESS allows Garrett to make new turbo models available to the public. The development of these wheels still go through the strenuous and rigorous process Garrett follows when developing any other wheel to be offered to the public. This means, proper consideration is placed not only on the cutting edge of aerodynamics and profiles, these units have to be reliable (OEM level) as well as safe during operation. While other "billet wheel" manufacturers might choose to "maximize" the flow area of the compressor wheel to achieve flow via shear mass and area (size) at the risk of "weakening" the wheel, Garrett's focus is more on efficiency through aerodynamics and profiling the wheel to ensure the structural integrity of the wheel is not compromised.

You do not want the wheel to come apart at 150,000 RPMs! Pay close attention to the unique profile of the Garrett wheels. Whether these new wheels are forged and machined (happens to have the "billet" look), or once they are sent through the traditional cast process (to reduce cost to you while performance is maintained), the GTX series of turbos will allow you to set new performance standards and take your turbo application to new heights.