- Knock resistance characteristics (knock limit) of the engine: Since every engine is vastly different when it comes to knock resistance, there is no single answer to "how much." Design features such as combustion chamber geometry, spark plug location, bore size and compression ratio all affect the knock characteristics of an engine.

- Ambient air conditions: For the turbocharger application, both ambient air conditions and engine inlet conditions affect maximum boost. Hot air and high cylinder pressure increases the tendency of an engine to knock. When an engine is boosted, the intake air temperature increases, thus increasing the tendency to knock. Charge air cooling (e.g. an intercooler) addresses this concern by cooling the compressed air produced by the turbocharger

- Octane rating of the fuel being used: octane is a measure of a fuel's ability to resist knock. The octane rating for pump gas ranges from 85 to 94, while racing fuel would be well above 100. The higher the octane rating of the fuel, the more resistant to knock. Since knock can be damaging to an engine, it is important to use fuel of sufficient octane for the application. Generally speaking, the more boost run, the higher the octane requirement.

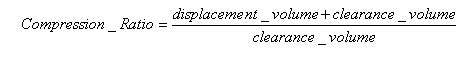

Now that we have introduced knock/detonation, contributing factors and ways to decrease the likelihood of detonation, let's talk about compression ratio. Compression ratio is defined as:

or

where CR = compression ratio Vd = displacement volume Vcv = clearance volume

where CR = compression ratio Vd = displacement volume Vcv = clearance volume

The compression ratio from the factory will be different for naturally aspirated engines and boosted engines. For example, a stock Honda S2000 has a compression ratio of 11.1:1, whereas a turbocharged Subaru Impreza WRX has a compression ratio of 8.0:1.

There are numerous factors that affect the maximum allowable compression ratio. There is no single correct answer for every application. Generally, compression ratio should be set as high as feasible without encountering detonation at the maximum load condition. Compression ratio that is too low will result in an engine that is a bit sluggish in off-boost operation. However, if it is too high this can lead to serious knock-related engine problems.

Factors that influence the compression ratio include: fuel anti-knock properties (octane rating), boost pressure, intake air temperature, combustion chamber design, ignition timing, valve events, and exhaust backpressure. Many modern normally-aspirated engines have well-designed combustion chambers that, with appropriate tuning, will allow modest boost levels with no change to compression ratio. For higher power targets with more boost, compression ratio should be adjusted to compensate. There are a handful of ways to reduce compression ratio, some better than others. Least desirable is adding a spacer between the block and the head. These spacers reduce the amount a "quench" designed into an engine's combustion chambers, and can alter cam timing as well. Spacers are, however, relatively simple and inexpensive. A better option, if more expensive and time-consuming to install, is to use lower-compression pistons. These will have no adverse effects on cam timing or the head's ability to seal, and allow proper quench regions in the combustion chambers.