Let’s stop for a second and think about the way a crankshaft is designed. On one end, you have your flywheel, torque converter, or a clutch. On the other, you have your timing chain / belt / gear drive, and then a small “snout” sticking out on which to bolt your damper and any needed accessories. In between all of that, you have a main caps and bearings that hold your crankshaft in the motor. Sometimes there are only two, four, or, on newer engines, six main caps that go over the crankshaft and then bolt to the actual engine block. This keeps your crankshaft where it should be. Finally, you have the rods, pistons, wristpins and rings. This is where all of the crankshaft twist and harmful “harmonics” are truly started.

Within a motor, something has to be off the centerline of the crankshaft so that as the crankshaft turns one revolution, a piston is pushed to the top and then pulled to the bottom

Within a motor, something has to be off the centerline of the crankshaft so that as the crankshaft turns one revolution, a piston is pushed to the top and then pulled to the bottom

Your pistons and components have to travel up and down the cylinder, to the top of the motor and then to the bottom. If you think about that motion within a motor, something has to be off the centerline of the crankshaft so that as the crankshaft turns one revolution, a piston is pushed to the top and then pulled to the bottom. However, if that stroke is a firing stroke, where fuel is compressed and combusted, that piston is then also forced downward and that is what actually produces your power.

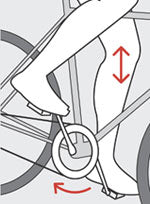

Think about riding a bicycle and the way you pedal the bike to move. The pedals themselves are like the pistons and the rod between the pedal and the crank sprocket is just like your connecting rods. The pedal arms have to be off the centerline of the crank in order for you to make a circle with the pedals and move your bike forward. Your crankshaft and pistons can be viewed in the same light. Because something has to be off the centerline of the crankshaft in order to function, the leverage of that connection to the crank is very high. That is why the crankshaft will twist as the system is forced to rotate when the engine is fired.

The pedals on a bike act like the pistons and the crank arm between the pedal and the chainring is just like your connecting rods.

While your motor is running, you have some pistons that are being pushed downward on a power stroke, some that are being pulled down by the crankshaft, and then there are some that are being pushed upward by the crankshaft. Now think about this entire system happening 8,000+ times per minute! Even further, think about all of these different actions that are taking place, and then imagine them happening on the same piece of metal - the crankshaft. These actions make that shaft twist in one direction away from its natural home location, and then when it tries to come back to that home location, its momentum makes it travel past its original location and farther in the other direction. This is what I measure when damper testing and the measure magnitude of that action is, Degrees of Twist – Peak to Peak. That is called crankshaft twist. That is what breaks parts and robs you of horsepower when there is nothing to counteract and eliminate the twist. In this system, the worst torsional vibrations, or twist, will always occur at the farthest point from the greatest load, or the heaviest mass. A torsional twist is defined as a twist without a bend. If you get too much of this twist, you will have a bend and this will cause engine and or crank failures. Think about twisting a piece of rope over and over, you can make one or two revolutions and nothing happens. Then after that it starts to get a wave in it, and then as you twist more, the rope will pull your hands closer together.

Once these vibrations get to the front of the motor, something there needs to counteract that motion. That is where the damper comes into play. The damper’s job is to absorb and counteract as much of the twist as it possibly can. If you have the right damper on your motor, almost all of the twist can be eliminated. However with the wrong damper virtually all of the twist can remain. A dampers job is to rebound, the recoil of a spring. In this case the spring is your crankshaft twisting and when it tries to rebound past that natural state we discussed earlier, that is when the damper needs to stop it. You may be wondering what that has to do with HP? Remember from above what is also at the front of your motor - your camshaft drive. If the front of your crankshaft is twisting, then your camshaft drive is being pulled and relaxed and pulled as the snout of the crank twists. If your camshaft position is being changed or varies, then the engine cannot properly induce, combust and remove the fuel. That means a loss in power! You must have a reliable damper that is capable of properly combating these vibrations and twist. Your stock damper, or stock style damper, is simply a piece of soft steel that has a rubber ring that has been melted in between another steel ring. The inherent problem with that design is that there is no way to maintain concentricity of the inertia ring during manufacturing. Therefore, the damper has to be machined and balanced after the inertia weight has been bonded to the rubber strip. That means when the outer ring slips you lose your timing marks, damper balance and concentricity! The stock damper works just fine as long as you do not make many changes to the motor. When you start changing HP and RPM you cannot count on your stock damper to do its job. Not to mention if that damper is old and worn out, the outer ring has a good chance of slipping or even separating from the rest of the damper and coming off your engine completely!Many different styles of aftermarket dampers are available. Through many years of testing and tuning, the O-ring style Elastomer damper has proven to be the best choice for performance applications, especially when high RPM is being applied. Additionally, this style is re-buildable and even tunable for your particular engine.

Aftermarket dampers are available from 5 to 15 lbs, in steel and aluminum, with serpentines, HTD, Gilmer, V groves, magnets in the shell, or just about anything you could ever want on them. These dampers also vary widely in the outside diameter of the damper itself. One of the biggest size challenges comes with the new tuner or import market. These small motors are making lots of HP and turning lots of RPM!

Aftermarket ATI Super Dampers are available from 4 to 17 lbs, in steel and aluminum, with serpentines, HTD, Gilmer, V groves, magnets in the shell, teeth cut into a steel shell, or just about anything you could ever want on them. These dampers come in diameters of 5” to 8” and thicknesses from 1.1” to 2.5”. One of the biggest size challenges comes with the Import Car Market. These small motors are making lots of HP and turning lots of RPM and usually have huge cylinder pressures with turbos blowing in 20+ lbs of boost! The stock Japanese dampers are not any different than stock American dampers in design, except for their size. The average size of the Import stock damper is around 5 ½ inches. Some import dampers are VERY poorly attached with 4 bolts holding the damper to a slip on lower timing belt drive and the “damper” bolt holding on that gear. Terrible design for high performance and you are asking for trouble if this is not addressed.

The average size of the Import stock damper is around 5 ½”.

The biggest problem with a smaller damper is that you have to be able to have enough inertia weight to make the damper do its job. Think about your common “Power Pulleys.” They may add some power by slowing down all of your accessories, but they will hurt your engine life and your power at some RPM ranges. Power Pulleys are not the right way to make power! In the long run power pulleys will yield failures in your engine and components on your car, especially flywheel bolts coming off and oil pump failures. That stands true for Imports and American cars.

Hopefully, this article has cast some light on crankshaft dampers. They are not black magic, just something that most people never think about. Chances are that your stock damper is old, and that the rubber has started to crack and wear out. Or you might have a cheaper aftermarket damper that is nothing more than a polished up stock damper design. Like I said, most people never check out their damper because they never realized what a critical component it is.